Produktgrupper

Frankering

Printere og MFP

.jpg?v=1510731377706)

Makulering

Harddisk sletting/ makulering

.png?v=1692961146943)

Kaffe og Kaffemaskiner

.jpg?v=1510731590245)

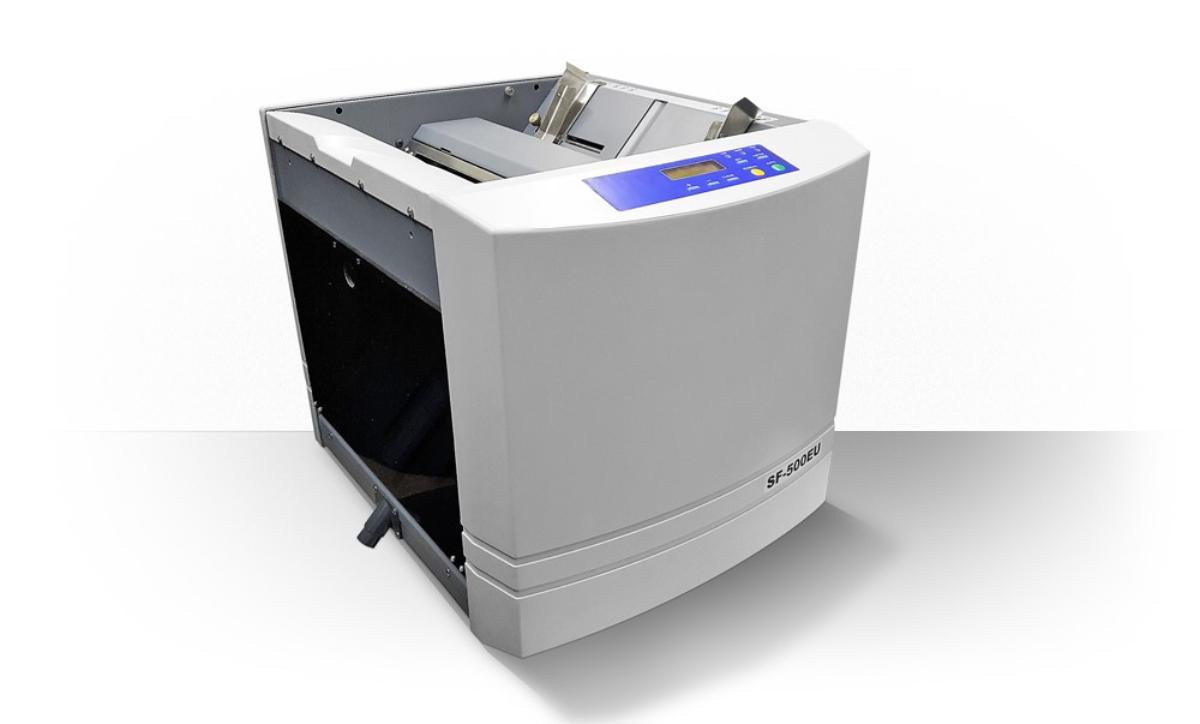

Konvoluttering

.jpg?v=1507104564867)

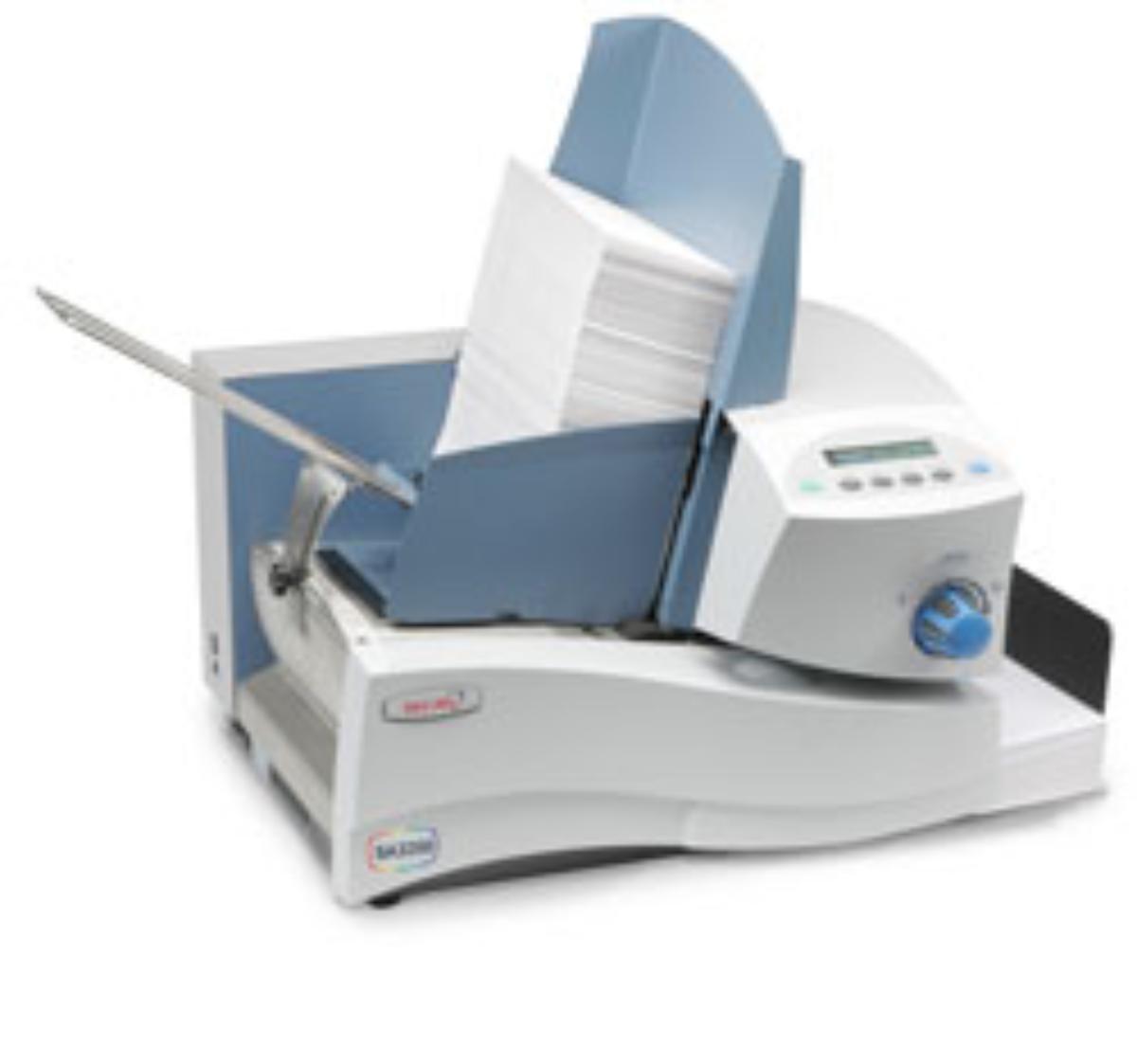

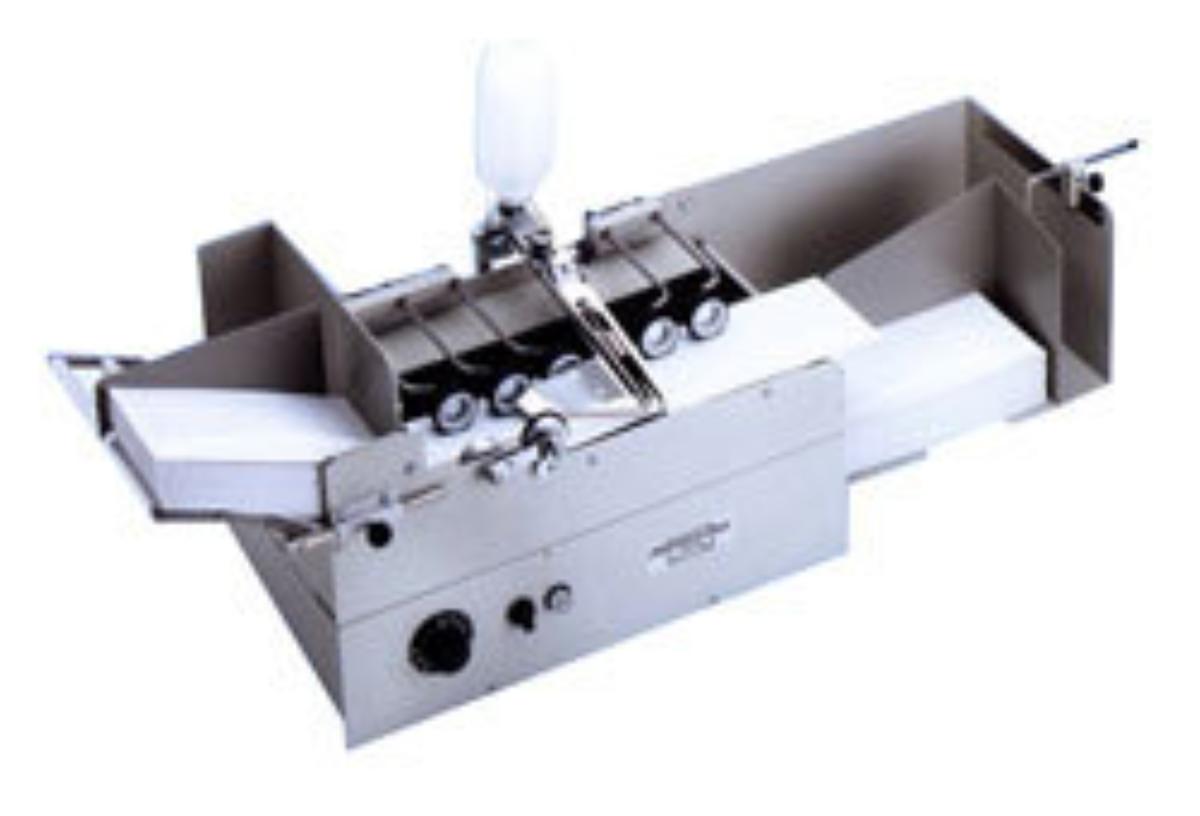

Bretting/Fals

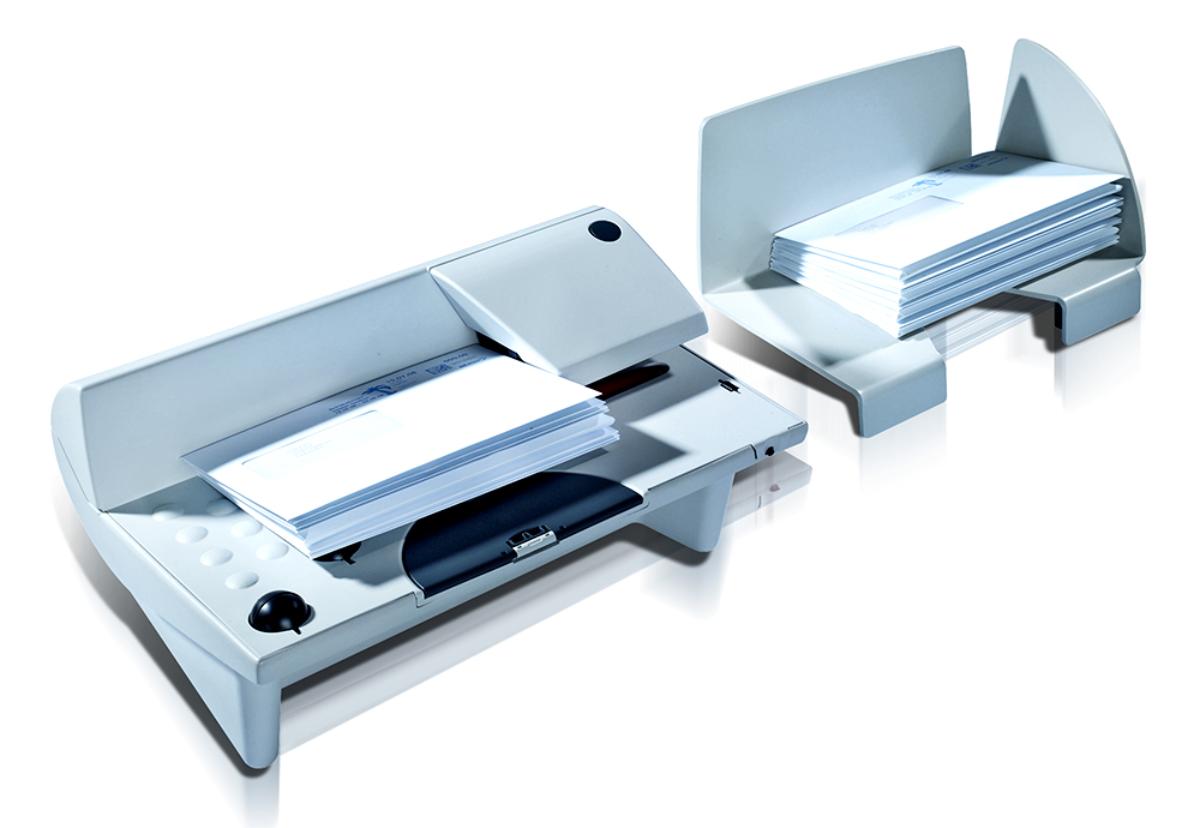

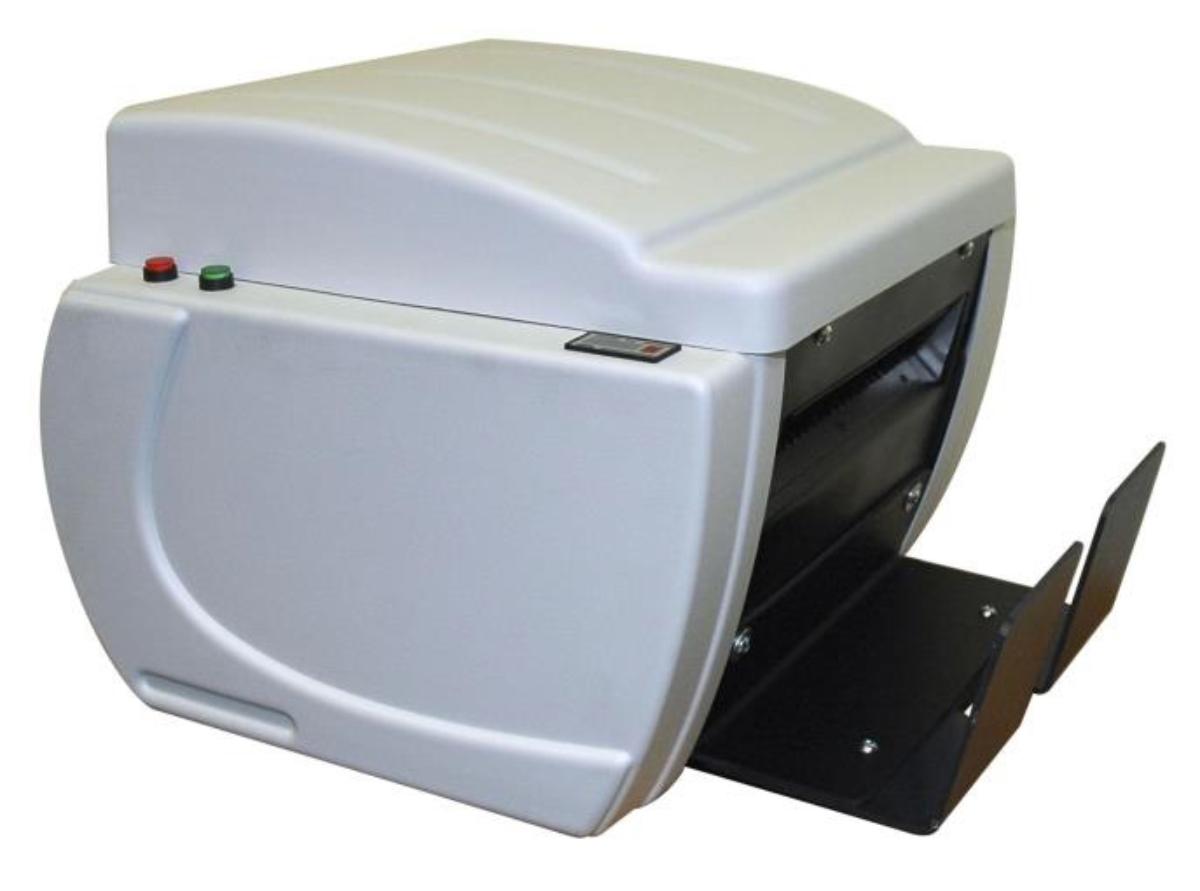

Brevåpnere

.jpg?v=1507105655484)

Skjæremaskiner

Innbinding

.jpg?v=1510065196239)

Laminering

.jpg?v=1507106312164)

Pakkefyll

Adressering

Booklet Maker

Brevlukker og tellemaskin

Jogger

.jpg?v=1507124585416)

Kortproduksjon

Liminnbinding

.jpg?v=1510315906029)

Rillemaskiner

Stiftemaskiner

.jpg?v=1507105087348)

Visittkortkutter

Pressfals maskiner

.png?v=1511511724569)

.png?v=1511511724656)

.png?v=1655111036329)

.png?v=1655110922741)

.png?v=1655110846425)

.jpg?v=1511858415200)

.jpg?v=1511858664636)

.jpg?v=1511858419165)

.jpg?v=1511858416883)

.gif?v=1676971018860)

.jpg?v=1511858417671)

.jpg?v=1511858418427)

.jpg?v=1511858415326)

.png?v=1506325277045)