Konvolutteringsmaskiner fra Böwe

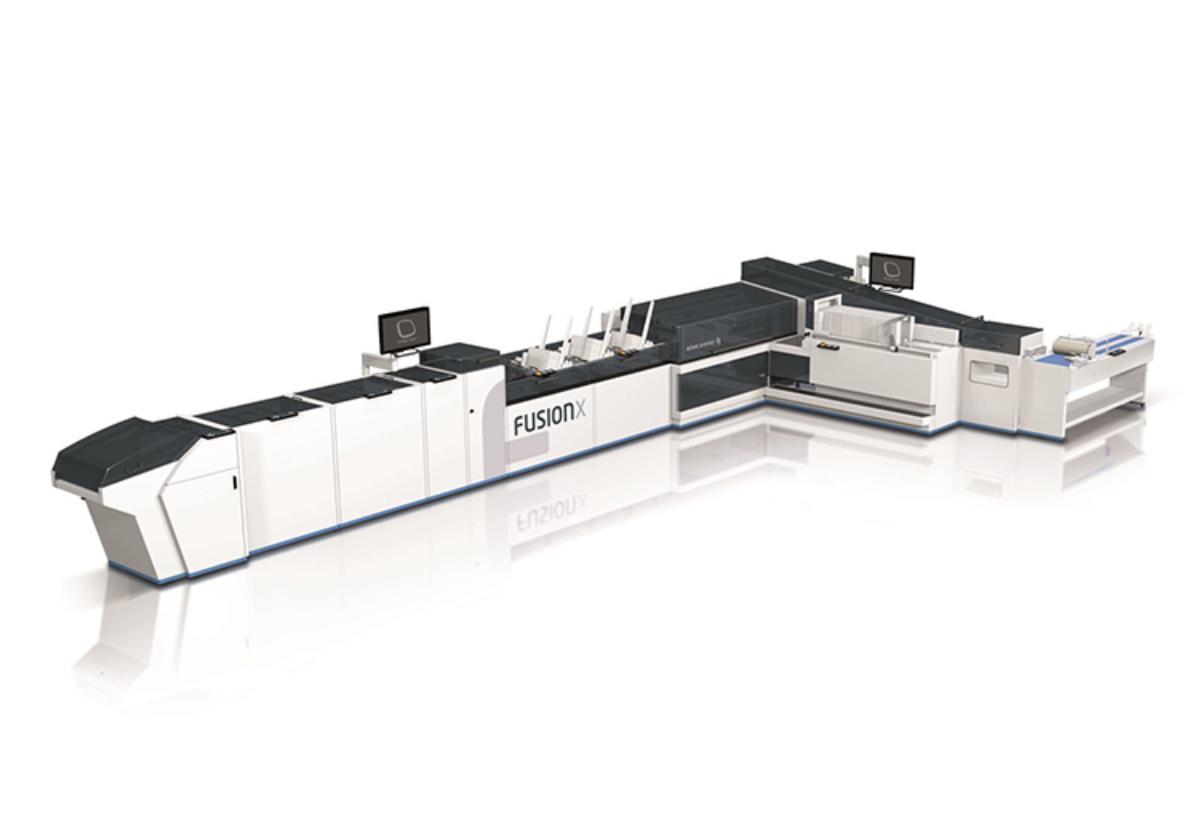

FusionX

Kontakt oss for pristilbud.

Få pristilbud

Turbo 8G

Kontakt oss for pristilbud.

Få pristilbud

Turbo Black

Kontakt oss for pristilbud.

Få pristilbud

Marathon

Kontakt oss for pristilbud.

Få pristilbud

Vario

Kontakt oss for pristilbud.

Få pristilbud

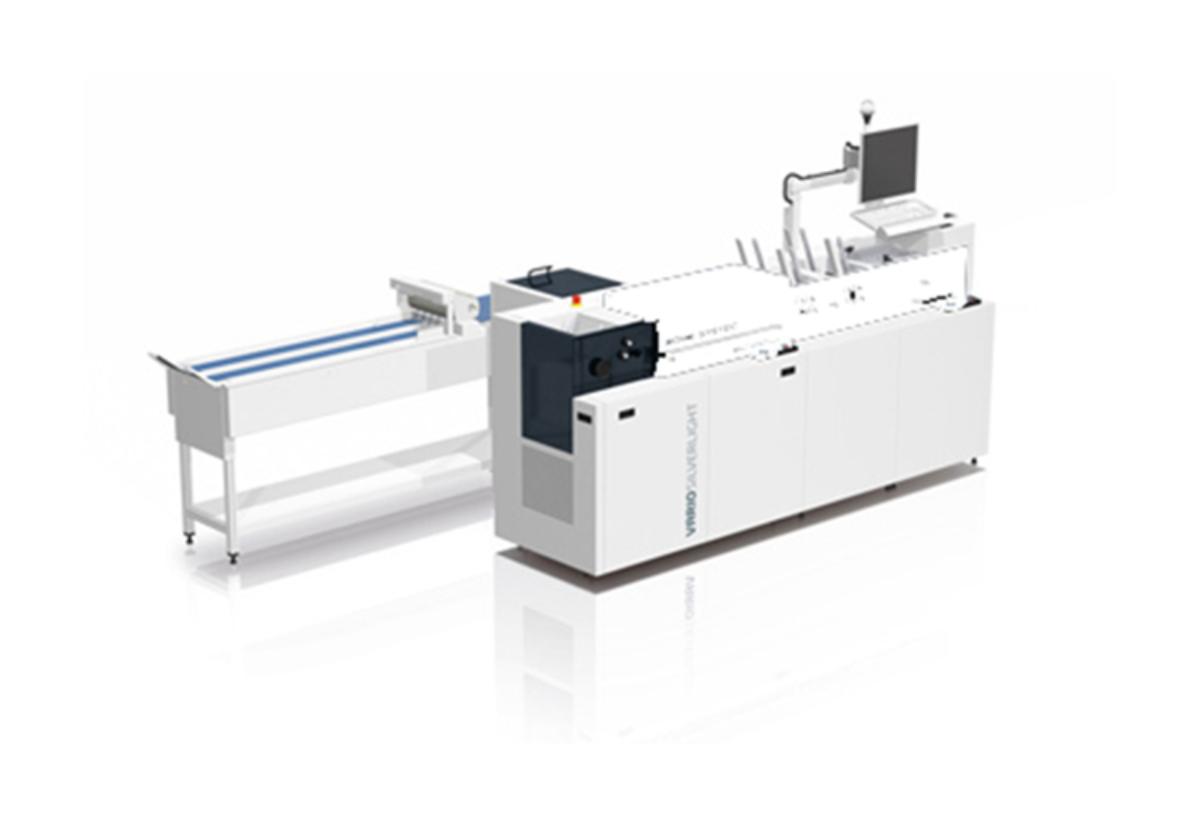

Vario Silverlight

Kontakt oss for pristilbud.

Få pristilbud

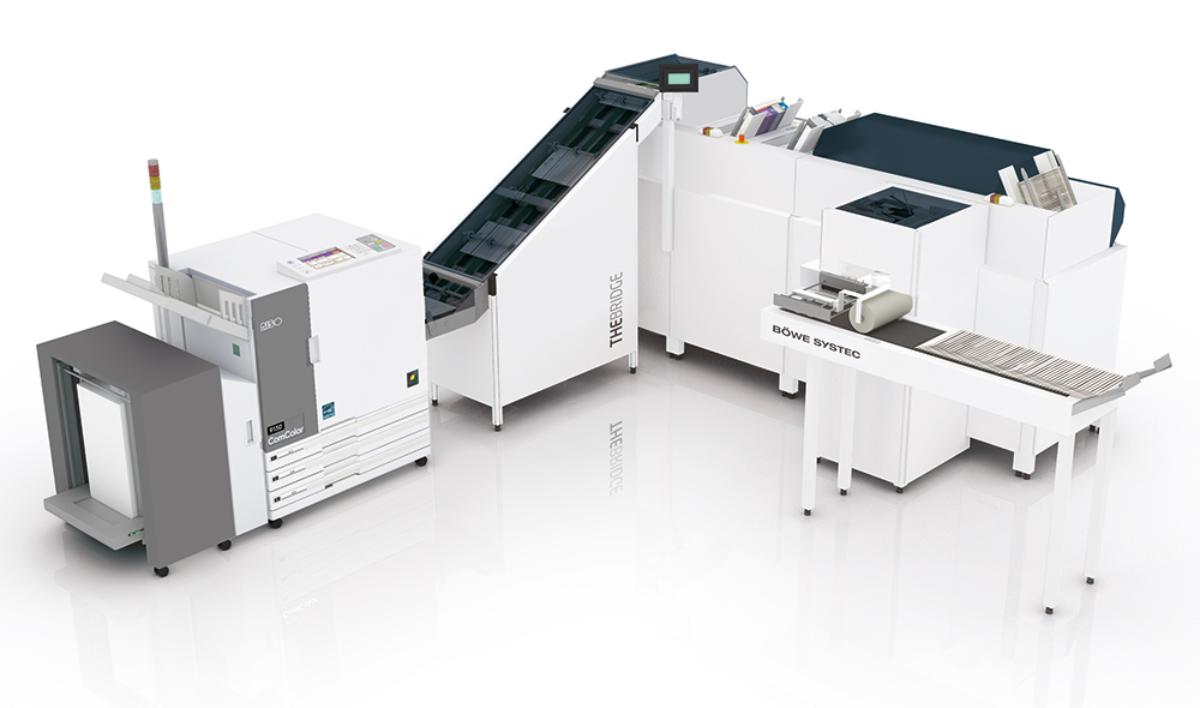

The Bridge

Kontakt oss for pristilbud.

Få pristilbud

Quattro

Kontakt oss for pristilbud.

Få pristilbud

Böwe Systec konvolutteringsmaskiner

- i samarbeid med Postrom Maskiner

Böwe Systec tilbyr en omfattende teknologi for innsetting, kortlogistikk og postrsystemer for et bredt spekter av applikasjoner. Alt fra grunnleggende oppsett til inteliggent og fullt automatiserte høyytelsessystemer for de største postvolumene og de mest krevende prosessene.

Postrom Maskiner er Böwes valg

Postrom Maskiner AS har siden 01.07.2013 vært distributør av maskiner produsert av Bowe Systec og tar service på alle Bowe installasjoner i Norge. Bowe Systec er ledende produsent av store konvolutteringsmaskiner, kortmaskiner og sealere og de valgte Postrom som representant i Norge fordi vi har et veldrevet serviceapparat med lang erfaring. Det at vi har en veldrevet serviceavdeling er et godt utgangspunkt for salg av Bowe produkter fordi vi vet at dette er helt avgjørende for at vi skal få et godt kundeforhold sammen.

Les mer om våre modeller i PRODUKTBOKA

.png?v=1506325277045)